Connecting the Dots Across Industries

Don’t get left behind with disconnected data.

What Does Connected Data Mean for Your Business?

At Team D3, we’re connecting the digital thread with customized solutions for the manufacturing, process and power, and AECO industries. Data-driven decision-making is the key to top performance, and our philosophy is that every piece of data holds valuable insights to leverage. With our connected data services, you can extract, aggregate, transform, and report on any data – anywhere and anytime.

Our strategy starts with a single source of truth and spans the entire dataverse. From there, you can streamline operations, make informed decisions, and propel your organization toward collaborative innovation and sustainability.

Value of Connected Data

Innovative products

Supply chain resiliency

Data consistency

Parallel development at scale

Reduce costs and save time

Insights and collaboration

The Industries We Serve

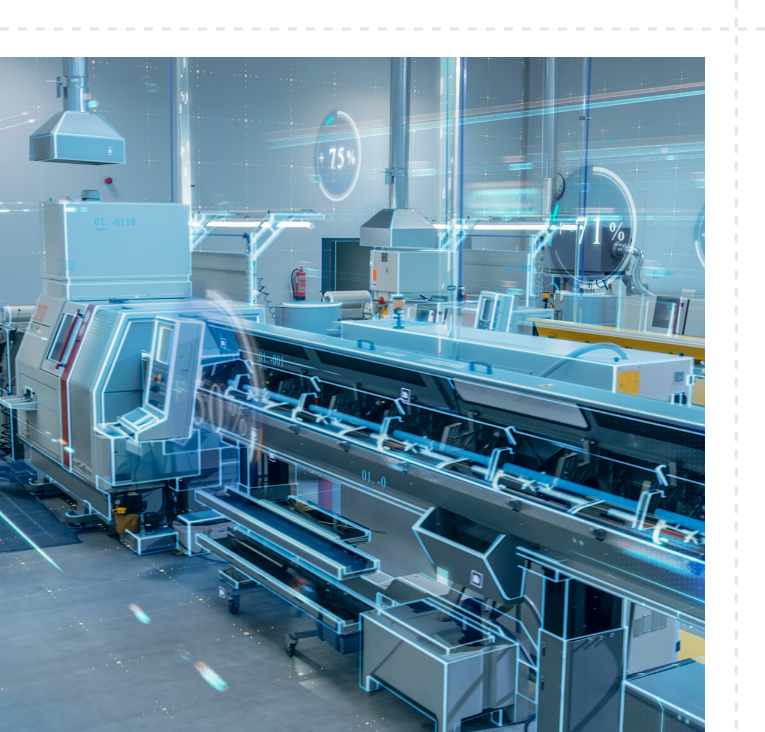

Manufacturing

Process & Power

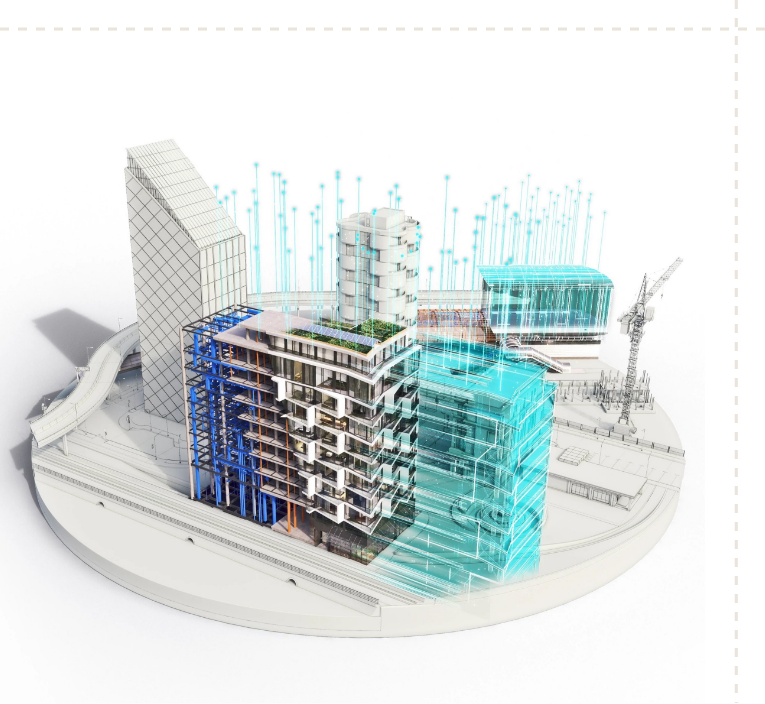

AECO

Connected Product Development

When different systems and devices can communicate and share data seamlessly, designers and manufacturers can gather valuable insights and make informed decisions during product development. Connectivity lets you collect and analyze real-time data from many sources. With this information, you can optimize handoffs from sales to engineering to production and ensure that product designs meet all desired specifications.

Connected data boosts collaboration, making it easier for teams to work together and manage changes during each stage of product development. Ultimately, connecting your data helps get products to market faster.

Industrialized Construction

Our platform tools connect data for building product manufacturing processes, from prefabrication to production. Construction teams can partner with designers and manufacturers to create scalable products for a specific need. The components resulting from this collaboration can be incorporated during a structure’s design phase and procured like equipment.

By adding automation to the mix, generating relevant data for AECO firms can be streamlined. You can save engineering time, automate workflows, improve collaboration, and deliver on convergence.

Digital Twin

Creating a digital twin helps you understand an asset’s behavior, performance, and condition in real-time. By monitoring the data collected, people in construction and engineering can identify potential issues, predict maintenance requirements, optimize energy efficiency, and ensure compliance with regulations.

A digital twin makes it easier for the people involved in the project, like architects, engineers, contractors, facility managers, and owners, to share information. With everything in one place, communication improves for more efficient project delivery and asset management.

Connecting Your Data

Your company produces more data than ever; connecting it all can feel daunting. Team D3 serves all industries, using a scalable data strategy to meet your needs. We can implement any level of our approach that makes sense for your business – from simple integrations and automation to a complete digital transformation.

Connected Data Solutions to Drive Efficiency

You can accelerate innovation and empower data-driven decisions with our expert solutions. Learn more from our resources below.

Frequently Asked Questions

Is “connected data” just another buzzword?

Connected data is not just a buzzword; it’s a transformative tool that refines how we make products, tailor solutions, and adapt to project needs with agility.

Connected data enables us to:

- Enhance accuracy: By delivering real-time product data, we ensure products are created and specified correctly and promptly, minimizing errors and the need for rework.

- Customize with confidence: Leveraging connected data, we can offer customized solutions faster, responding to project demands with unparalleled speed and precision.

- Drive product innovation: Insights from completed projects inform rapid product development, allowing us to iterate and innovate efficiently.

What Autodesk products are best for connected data initiatives?

Autodesk has a comprehensive product suite that drives connected data initiatives forward, like Fusion Manage, Informed Design, and the Autodesk Construction Cloud.

Is connected data conducive to remote work?

Yes! Connected data gives teams access to every piece of information, wherever they are. Teams can now review designs, see BOM items, change lifecycle states, and create and participate in change orders remotely.

Start Your Digital Transformation

Let’s navigate the complexities of connected data together.